The SSAW (Spiral Submerged Arc Welded) pipe is a type of welded steel pipe manufactured through a spiral forming process. Its unique structural characteristics and broad range of applications make it a key choice in pipeline engineering.

I. Features

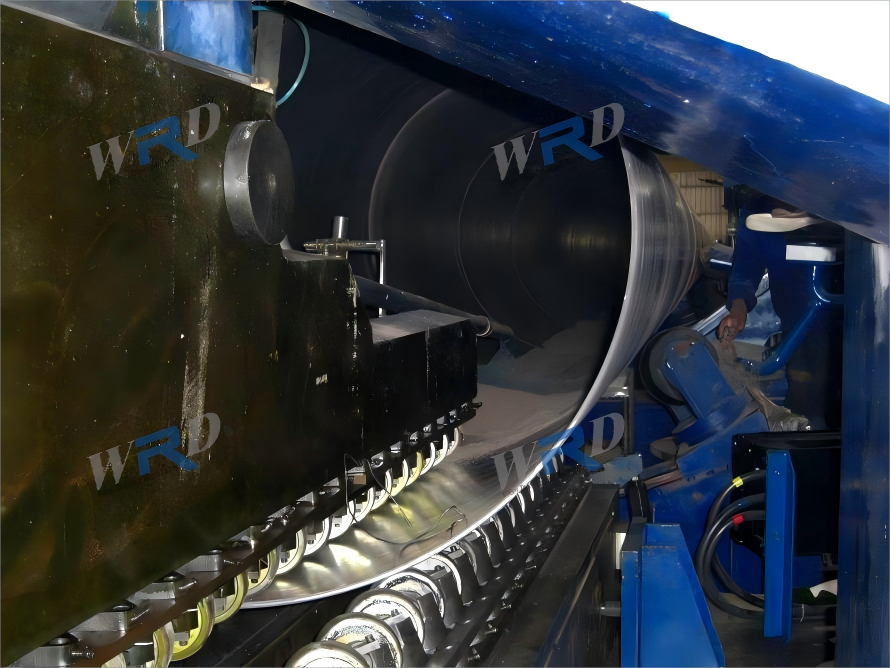

The most distinctive feature of spiral welded pipes is their helical seam. Unlike longitudinal welded pipes, the weld seam spirals around the pipe body, formed by continuously coiling steel strips at a specific angle. The pipe diameter typically ranges from 20 to 100 inches (508mm–2540mm), with adjustable wall thicknesses as needed. Thanks to the continuous spiral forming process, pipes can theoretically be produced in any length, significantly reducing the number of joints required in engineering projects.

II. Functional Advantages

1. High Structural Strength: The spiral weld distributes stress more evenly, providing superior pressure resistance compared to straight-seam pipes—especially important for high-pressure transmission pipelines.

2. Dimensional Flexibility: By adjusting the forming angle, the same equipment can produce pipes of various diameters, reducing capital investment. This adaptability is particularly advantageous for projects requiring multiple pipe sizes.

3. Cost Efficiency: Wider pipes can be produced using relatively narrow steel strips, improving material utilization. Continuous production also enhances manufacturing efficiency.

4. Broad Applications: Primarily used for long-distance transportation of oil, gas, and other fluids, as well as in hydraulic engineering and structural support. Its reliable sealing and pressure-bearing capacity are key selection factors.

III. Typical Applications

In oil and gas transportation, spiral welded pipes are the preferred choice for trunk pipelines due to their cost-effectiveness and reliability. In hydraulic engineering, their large diameters make them suitable for drainage pipes and culverts. Additionally, they are commonly used as load-bearing columns in large-scale construction projects like stadiums.

With their distinctive design and dependable performance, spiral welded pipes continue to play a vital role in various engineering projects. Advances in welding technology are expected to expand their applications even further.

About WRD

With long history of expertise in ERW pipe mill R&D and manufacturing, WRD offers complete pipe mills, serving clients in over 50 countries. Renowned for high precision, efficiency, and energy-saving performance, WRD holds ISO 9001 certification and is recognized as a National Specialized, Sophisticated, and Innovative Enterprise. The company is dedicated to delivering cutting-edge welded pipe production solutions for energy, construction, machinery, and related industries worldwide.

We supply solutions for:

▶ERW tube mills

▶Complete API 5L/5CT tube mills

▶DFT tube mills

▶SSAW pipe mills

▶Welded H-beam mills

▶Hot dipped galvanizing lines/ ZAM tube mill

▶Slitting and Cut-to length line

▶Rollers

Contact WRD

Phone: +86-13752728312 (WhatsApp )

E-mail: info@wrdtubemill.com