-

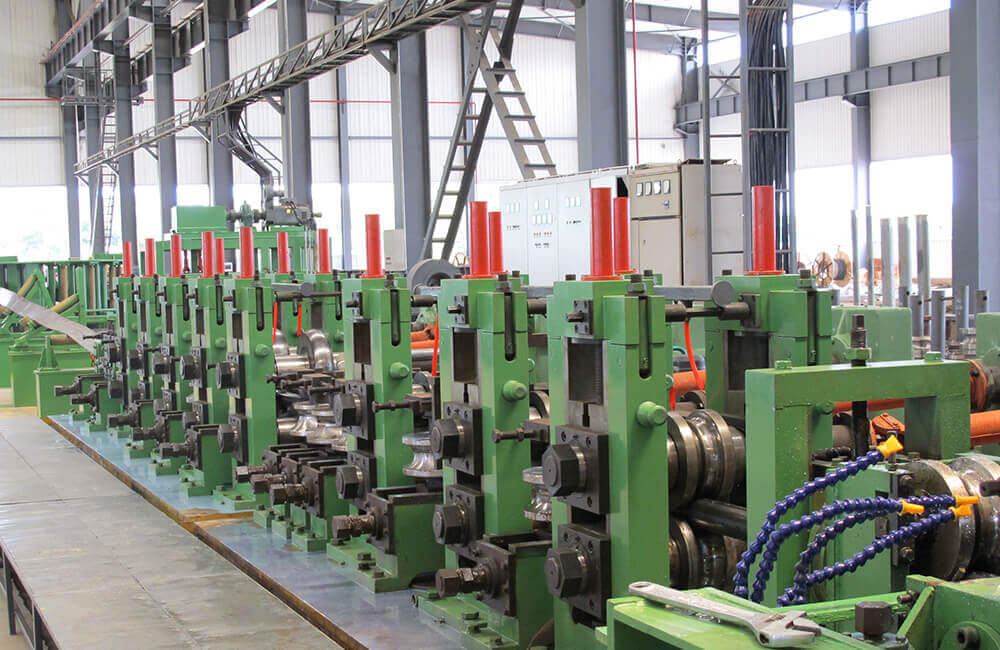

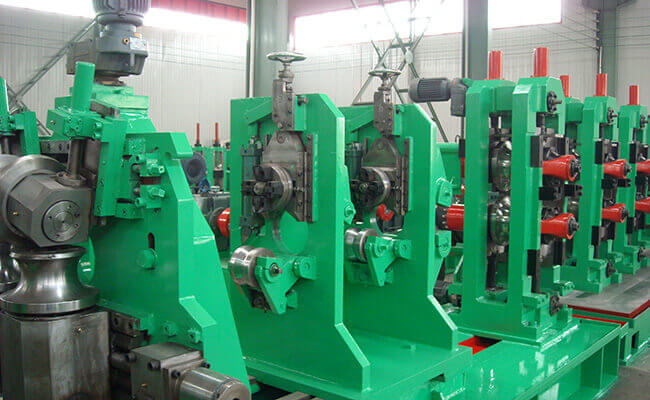

The “WFF” forming method has simple structure, convenient maintenance and high production efficiency. The rollers of the first four horizontal frames, the first and second vertical roller frames, and the third, fourth and fifth C-roll frames have commonality. The replacement specifications do not need to be replaced, only adjustment is required. Save 30% of the entire set of equipment rolls, save roll change time, improve production efficiency, and have a competitive advantage in the market competition. This molding method is the world's advanced technology, and the state of stress during the deformation process is more reasonable. Our company digested and absorbed on this theory, and applied this advanced molding technology to the unit, so that the unit reached the domestic advanced level.

-

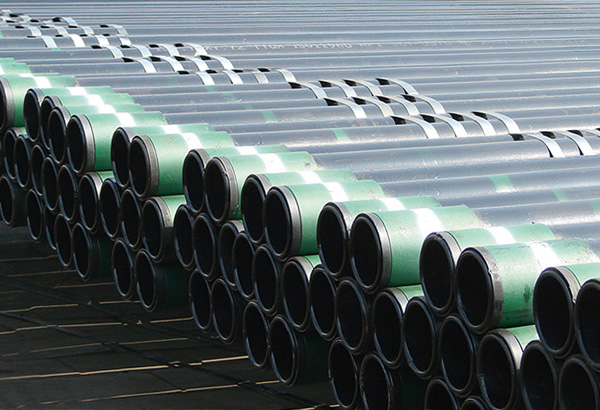

The "WFFX" forming method is especially suitable for the API pipe lines, and the stress state is more reasonable during the deformation process, which can save 50% of the roll. Based on this theory, our company is able to absorb this advanced molding technology into this unit, so that the unit can reach the international advanced technology level.

-

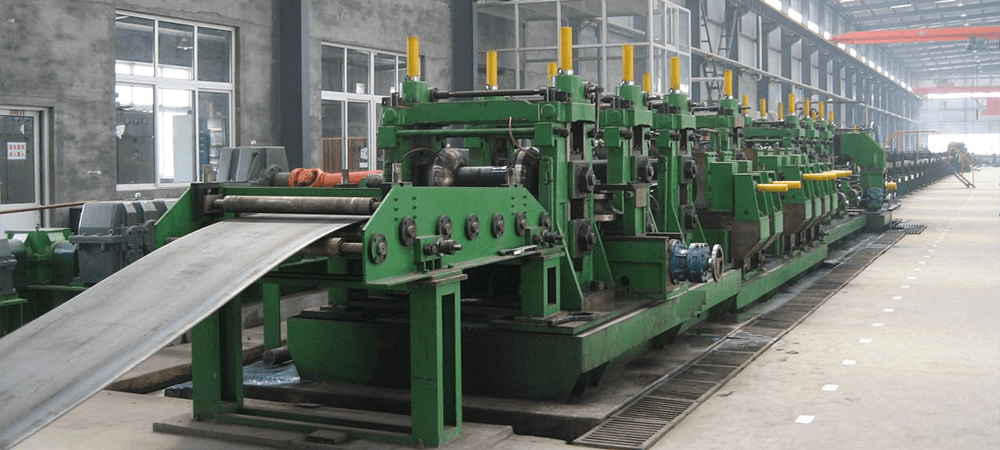

The production line adopts the mature, reliable, complete, economic applicable advanced technology, advanced equipment, to ensure product quality, cost, and the consumption indexes reach the advanced level, products have strong competitiveness in quality and price.