WRD Advantages

-

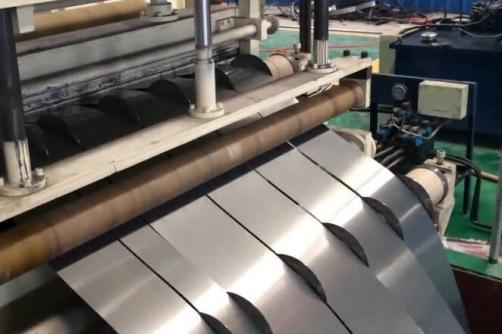

Wide Range of Production:Suitable for small wall thickness and more number of slitting strip(0.1-2.0mm), as well as high steel grade with large thickness slitting strip from 5mm up to 25mm thick and min. 500mm up to 2200mm width.

-

Flexibility:Slitter and cut-to-length could be separately designed and operated and also could be designed and operated as a combined one with both of slitting and cutting into lengths functions.

-

Precision Slitting:The width tolerance of finished strip can be controlled within ±0.05mm.

-

Practicality:It’s convenience to change the blade; Easy maintenance and lower operating cost.

-

Customization:Can be customized according to site space factors, raw materials, energy situation, product quality and capacity control requirements.