As an experienced comprehensive supplier of pipe equipment, WRD not only provides high-precision pipe mills, but also has a complete solution in the field of steel pipe surface treatment, covering three major technical routes: galvanizing (GI), aluminum zinc plating (Al Zn), and zinc aluminum magnesium (ZAM), meeting the stringent requirements of different industries for pipe material performance.

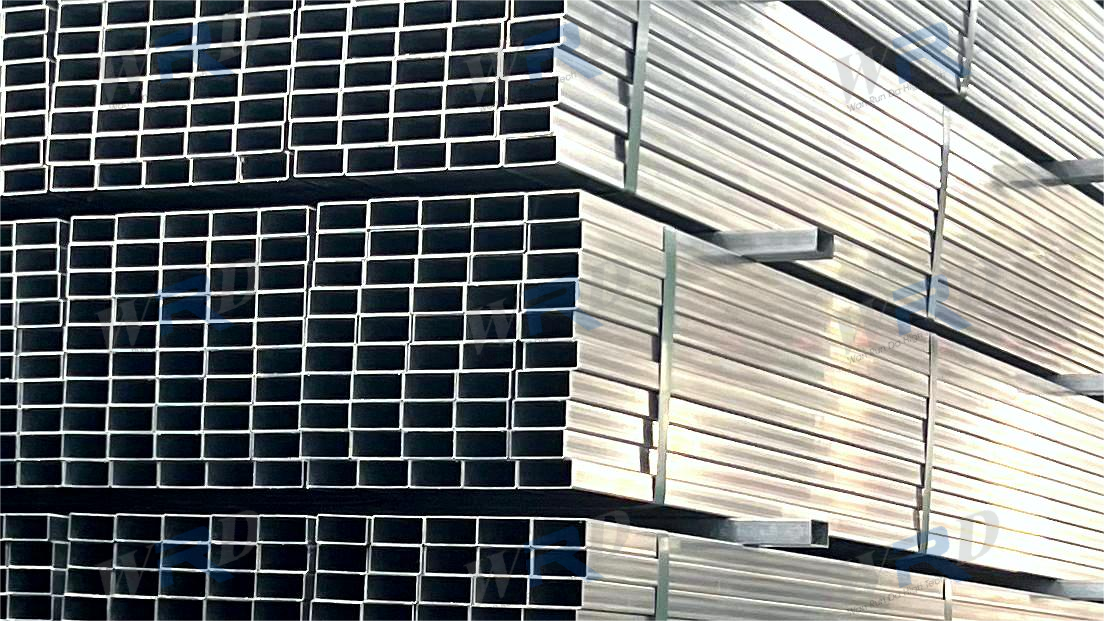

Galvanized pipe (GI pipe)

Galvanized pipes use hot-dip galvanizing technology to form a pure zinc coating on the surface of the steel pipe, which has excellent rust prevention performance and high cost-effectiveness. This type of steel pipe is mainly used in conventional fields such as building scaffolding, agricultural greenhouse skeletons, cable trays, etc., and is suitable for dry or ordinary corrosive environments. The thickness of the zinc layer is usually 30-300g/m ², which can provide 15-20 years of anti-corrosion protection under normal use conditions, making it the most economical and practical choice in infrastructure construction.

Aluminum zinc coated pipe (Al-Zn pipe)

Aluminum zinc coated pipes are coated with an alloy of aluminum, zinc, and trace silicon through a hot-dip process, which combines the high temperature resistance of aluminum with the cathodic protection properties of zinc. Its corrosion resistance is 3-5 times that of ordinary galvanized pipes, making it particularly suitable for high-temperature environments such as automotive exhaust pipes, industrial heat exchange equipment supports, and moderately corrosive environments such as chemical plant structural components. The service life of aluminum zinc coated pipes in coastal areas is significantly better than that of ordinary galvanized products.

Zinc aluminum magnesium pipe (ZAM pipe)

The zinc aluminum magnesium pipe adopts the zinc aluminum magnesium ternary alloy coating technology. By adding magnesium element, the coating has self-healing function, and the corrosion resistance can reach 8-10 times that of ordinary galvanized pipes. This type of high-end pipe is mainly used in fields such as photovoltaic support systems, marine engineering structural components, and new energy vehicle battery packs that require strict durability of materials. In projects such as Dubai Desert Photovoltaic Power Station, ZAM tubes have achieved 30-year maintenance free usage verification, becoming the preferred material for new energy and major infrastructure projects.

About WRD

With long history of expertise in ERW pipe mill R&D and manufacturing, WRD offers complete pipe mills, serving clients in over 50 countries. Renowned for high precision, efficiency, and energy-saving performance, WRD holds ISO 9001 certification and is recognized as a National Specialized, Sophisticated, and Innovative Enterprise. The company is dedicated to delivering cutting-edge welded pipe production solutions for energy, construction, machinery, and related industries worldwide.

We supply solutions for:

▶ERW tube mills

▶Complete API 5L/5CT tube mills

▶DFT tube mills

▶SSAW pipe mills

▶Welded H-beam mills

▶Hot dipped galvanizing lines/ ZAM tube mill

▶Slitting and Cut-to length line

▶Rollers

Contact WRD

Phone: +86-13752728312 (WhatsApp )

E-mail: info@wrdtubemill.com