In the modern metal processing industry, the slitting line plays an indispensable role. This automated system functions like a master tailor, precisely cutting wide metal coils into narrower strips of required widths, providing essential materials for subsequent manufacturing. Let’s explore the intricacies of this precision processing technology.

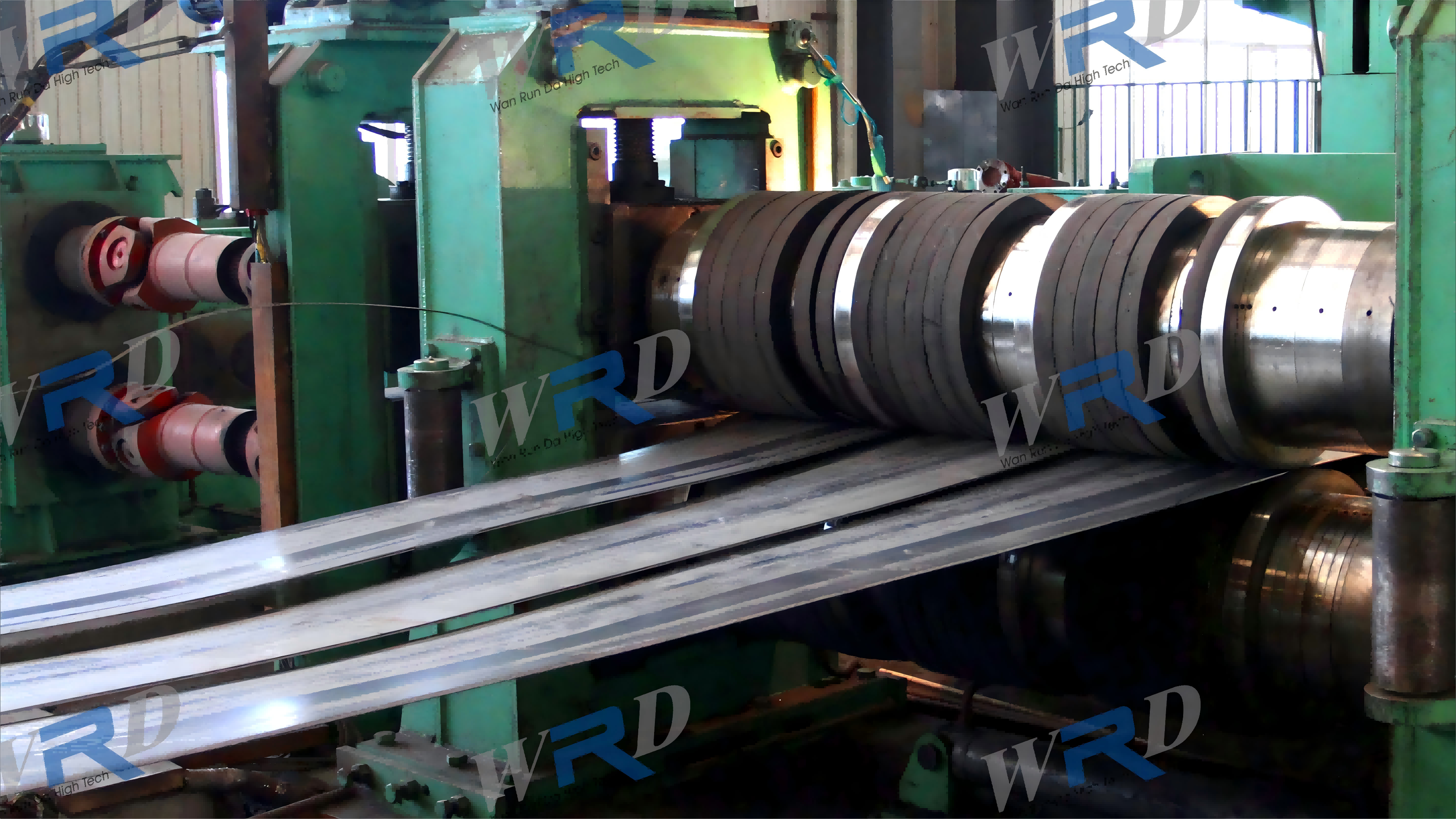

The core working principle of a slitting line relies on the precise coordination of circular blades to achieve longitudinal cutting of metal sheets. A standard production line consists of key components such as an uncoiler, leveling machine, slitting machine, tension control system, and recoiler. The uncoiler unwinds the metal coil, the leveling machine eliminates internal stress in the material, the slitting machine performs the cutting operation, and finally, the recoiler rewinds the slit strips.

In the overall configuration of a ERW tube mill, the slitting line serves as a crucial auxiliary equipment that plays a pivotal role. The primary function of this system is to precisely cut raw material coils into strips of varying widths according to production requirements, thereby providing customized raw materials for subsequent pipe forming processes. When the factory needs to produce welded pipes of multiple specifications, the slitting line can quickly and accurately slit the same batch of raw material coils into strips of different widths by adjusting blade spacing and process parameters, significantly enhancing the production line's flexibility and material utilization efficiency.

The technological advantages of slitting lines are evident in three key aspects:

1. Precision: Cutting accuracy can be far surpassing traditional shearing methods.

2. Automation: A standard slitting line requires less operators.

3. Efficiency: Continuous production enables 5-8 times higher output compared to single-sheet cutting.

With technological advancements, modern slitting lines are evolving toward greater intelligence. High-end models now feature automatic blade-changing systems, real-time monitoring, and intelligent edge-tracking systems, further enhancing productivity and product quality.

About WRD

With long history of expertise in ERW pipe mill R&D and manufacturing, WRD offers complete pipe mills, serving clients in over 50 countries. Renowned for high precision, efficiency, and energy-saving performance, WRD holds ISO 9001 certification and is recognized as a National Specialized, Sophisticated, and Innovative Enterprise. The company is dedicated to delivering cutting-edge welded pipe production solutions for energy, construction, machinery, and related industries worldwide.

We supply solutions for:

▶ERW tube mills

▶Complete API 5L/5CT tube mills

▶DFT tube mills

▶SSAW pipe mills

▶Welded H-beam mills

▶Hot dipped galvanizing lines/ ZAM tube mill

▶Slitting and Cut-to length line

▶Rollers

Contact WRD

Phone: +86-13752728312 (WhatsApp )

E-mail: info@wrdtubemill.com