In modern industrial production, high-frequency welded (HFW) pipes have become indispensable materials in construction, machinery, automotive, and other fields due to their efficiency and precision. But how does an ordinary steel coil transform into pipes of various specifications? Let’s uncover the mystery behind this manufacturing process.

The journey begins with the preparation of the steel coil. The coiled steel strip is gradually unwound by an uncoiler and then passes through a leveling machine to eliminate curvature and internal stress, ensuring precision in subsequent processes. Though this step may seem simple, it directly impacts the final product quality.

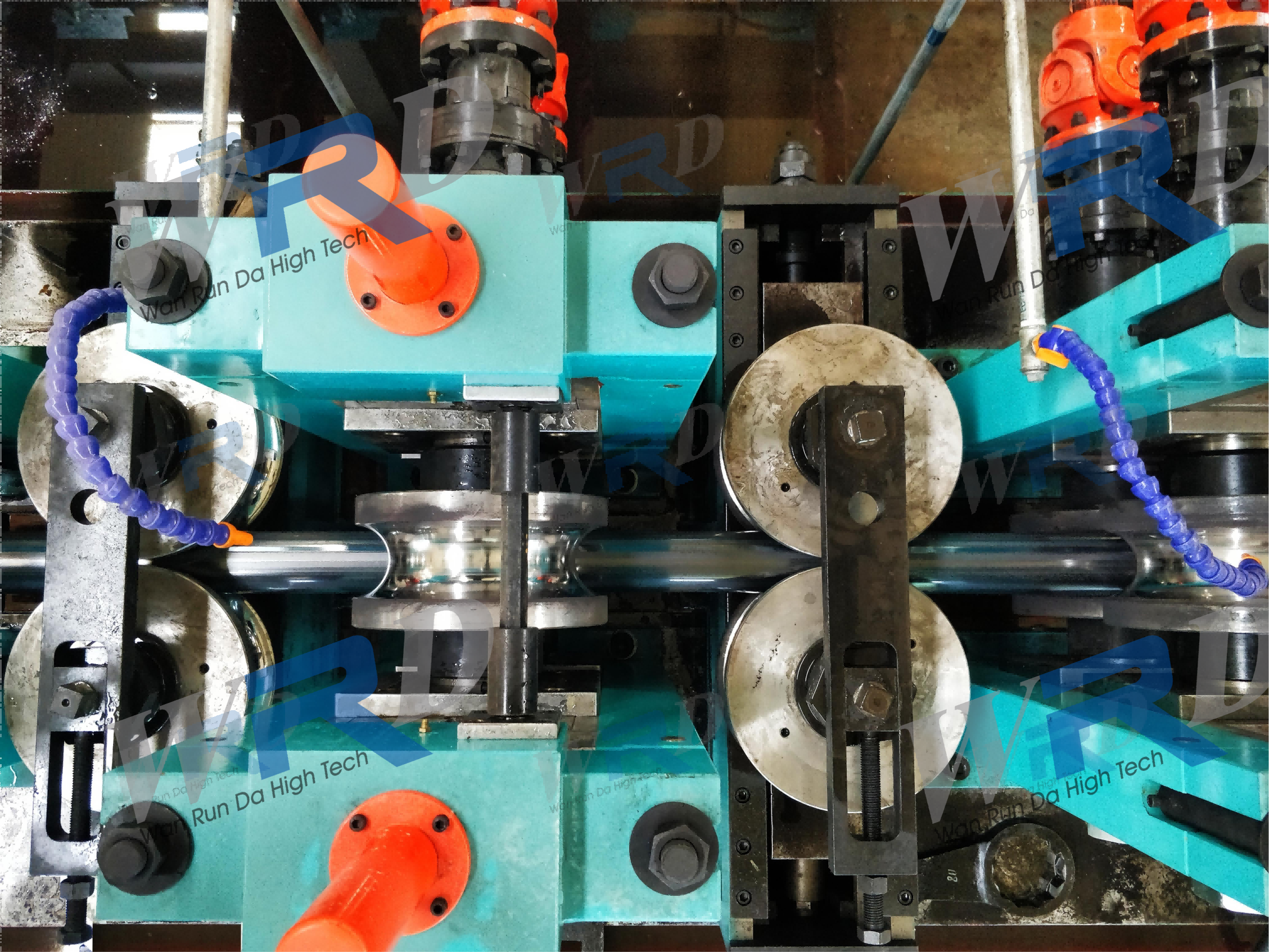

Next comes the forming stage. The flattened steel strip is gradually shaped into a cylindrical pipe through a series of precisely arranged rollers. The angles and spacing of these rollers are carefully calculated to ensure smooth and uniform deformation. At this point, high-frequency welder plays a magical role—when the edges of the steel strip approach each other, the heat generated by the current instantly raises the temperature to welding levels.

The welding stage is the heart of the process. The edges of the formed pipe are tightly pressed together by squeeze rolls, and under the influence of high-frequency welder, the metal melts and fuses rapidly. This welding method is fast, efficient, and produces consistent weld quality. Notably, modern HFW machines are equipped with automatic control systems that monitor and adjust welding parameters in real time.

After welding, the pipe undergoes sizing. Precision-calibrated sizing rollers ensure the roundness and dimensional accuracy meet standards. At this stage, the pipe is nearly complete, but to enhance its performance, online heat treatment is often applied to relieve welding stress and improve material properties.

Finally, the finishing process takes place. The pipe is cut to the required length by a flying saw, undergoes rigorous quality inspection, and may receive surface treatments like galvanization before packaging. The entire production process is highly automated, transforming steel coils into finished pipes in just minutes.

With technological advancements, modern HFW pipe production lines have become increasingly intelligent. Automated control systems monitor parameters in real time to ensure product consistency, while big data analytics optimize precision and efficiency. These innovations not only improve quality but also expand the applications of HFW pipes.

From construction scaffolding to automotive exhaust pipes, from furniture frames to industrial machinery, HFW pipes serve countless aspects of modern life with their excellent performance and cost-effectiveness. And it all starts with an ordinary steel coil, undergoing a series of precise processes to become a vital material supporting modern industry.

About WRD

With long history of expertise in ERW pipe mill R&D and manufacturing, WRD offers complete pipe mills, serving clients in over 50 countries. Renowned for high precision, efficiency, and energy-saving performance, WRD holds ISO 9001 certification and is recognized as a National Specialized, Sophisticated, and Innovative Enterprise. The company is dedicated to delivering cutting-edge welded pipe production solutions for energy, construction, machinery, and related industries worldwide.

We supply solutions for:

▶ERW tube mills

▶Complete API 5L/5CT tube mills

▶DFT tube mills

▶SSAW pipe mills

▶Welded H-beam mills

▶Hot dipped galvanizing lines/ ZAM tube mill

▶Slitting and Cut-to length line

▶Rollers

Contact WRD

Phone: +86-13752728312 (WhatsApp )

E-mail: info@wrdtubemill.com