The direct-forming square pipe mill(DFT tube mills) is an automated production system that transforms steel strips directly into square tubes, offering the distinct advantage of streamlining traditional manufacturing processes by enabling continuous processing from raw material to finished product. Widely used in construction, machinery manufacturing, and furniture industries, this production line efficiently manufactures square tubes of various specifications.

Features

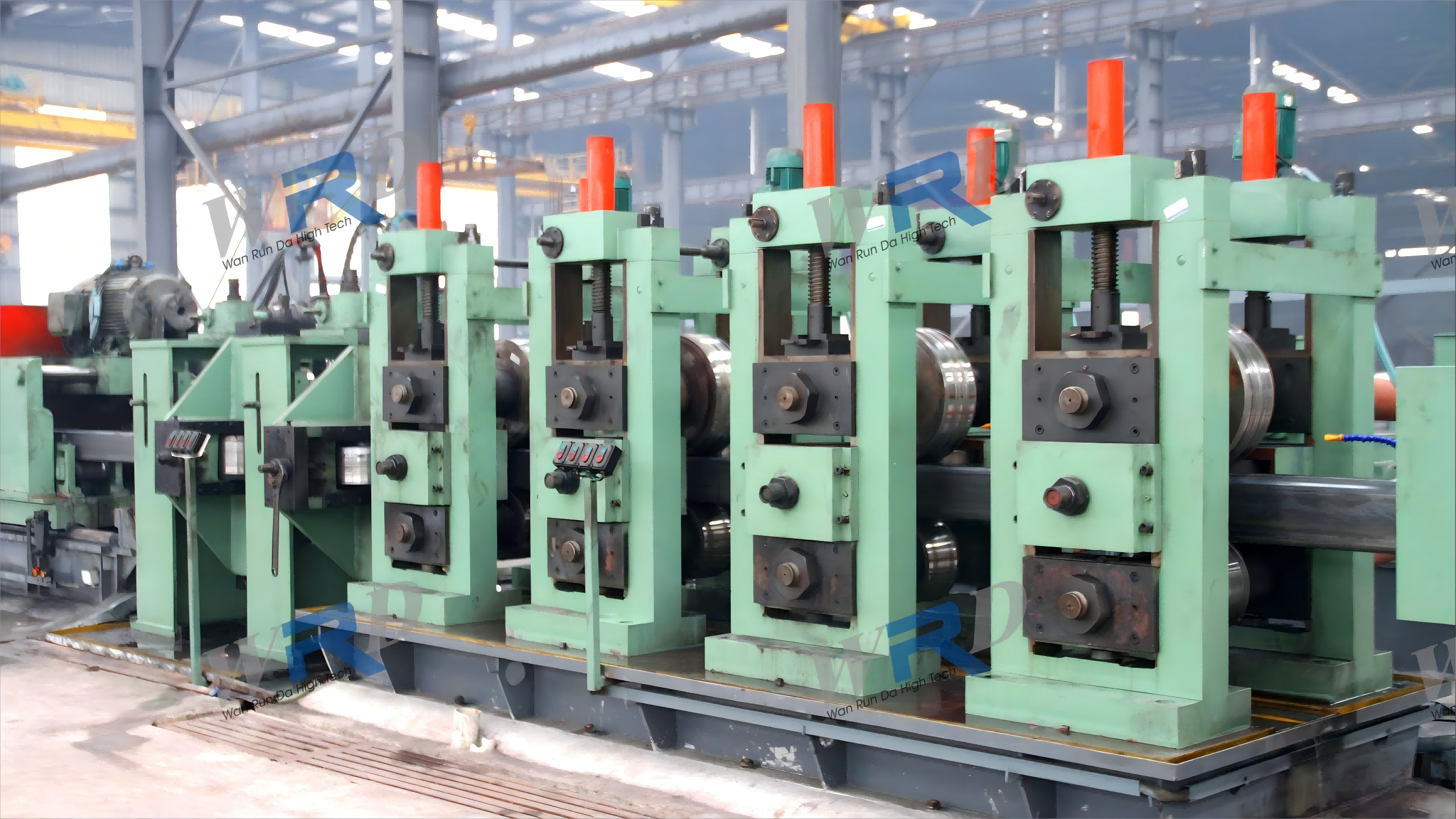

The direct-forming square pipe mill employs a multi-pass progressive forming process. Through a series of precision-designed roll-forming dies, the steel strip is gradually bent into a square cross-section. Unlike conventional methods that first form round tubes before squaring them, this system achieves direct roll-forming, eliminating intermediate steps. The resulting square tubes feature well-defined edges and corners with precise dimensional control, meeting the requirements of high-precision applications.

The production line typically consists of uncoiling, leveling, forming, welding, sizing, and cutting modules, all for continuous operation. Its modular design allows quick change for different tube specifications, significantly enhancing production flexibility.

Functional Advantages

1. High Efficiency: The direct-forming technology eliminates secondary processing steps found in traditional methods, dramatically improving production efficiency for large-volume orders.

2. Material Savings: By omitting the round-to-square conversion process, material deformation loss is reduced, improving raw material utilization.

3. Strong Adaptability: Adjustments to roll-forming dies and process parameters enable production of square tubes with different side lengths and wall thicknesses to meet diverse market demands.

4. Superior Weld Quality: High-frequency welding or laser welding technologies ensure weld strength comparable to the base material, making it suitable for load-bearing applications.

Typical Applications

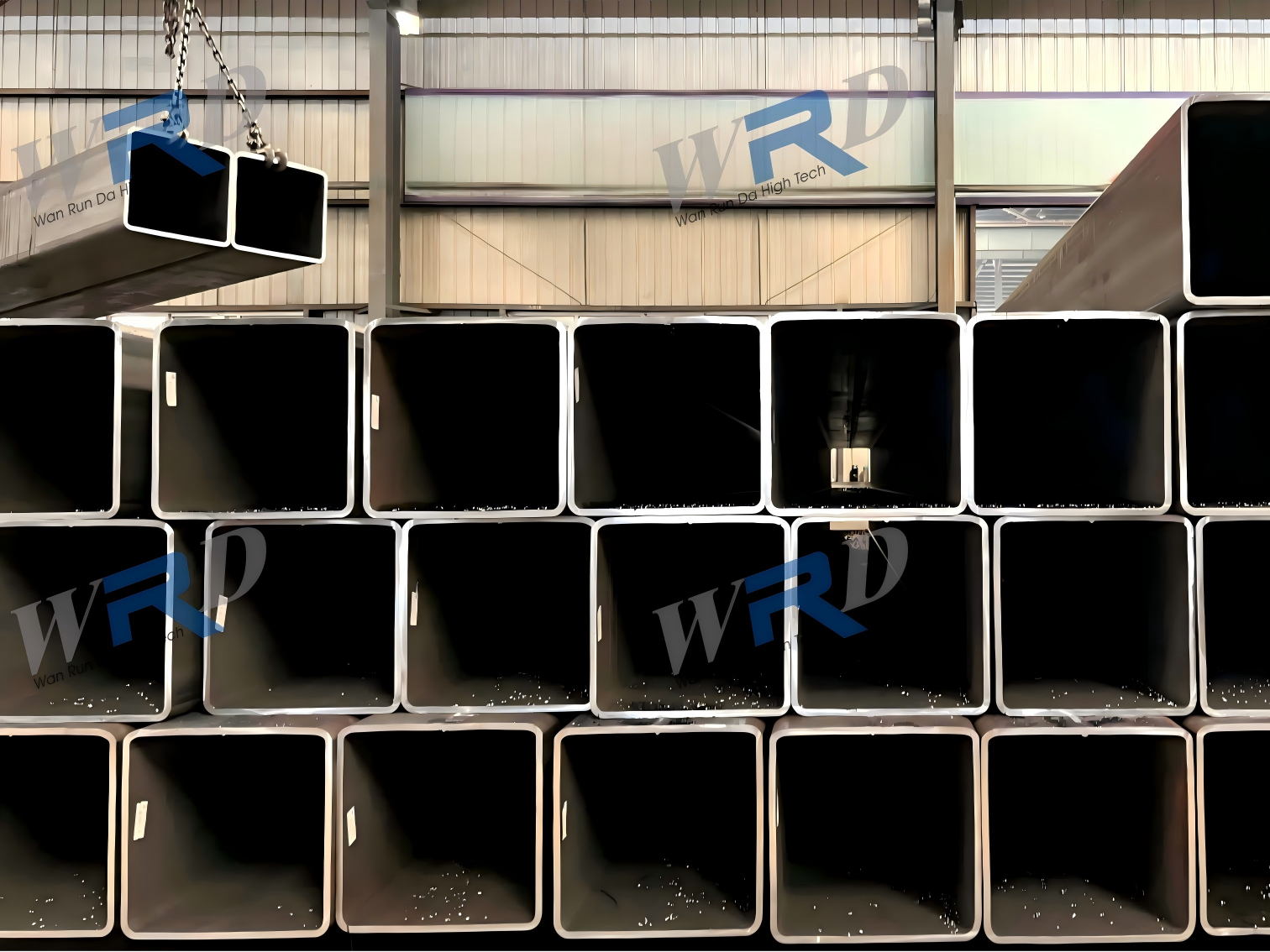

Square tubes produced by direct-forming mills are widely used in structural supports, shelving systems, door/window frames, and conveying equipment. Their high precision and consistency make them particularly suitable for standardized assembly requirements, such as modular construction and automated storage systems.

As manufacturing demands for efficiency and quality continue to grow, direct-forming square pipe mills are becoming the mainstream choice for square tube production due to their high efficiency and energy-saving characteristics. With the integration of smart technologies, these systems are expected to further enhance automation levels and product quality consistency in the future.

About WRD

With long history of expertise in ERW pipe mill R&D and manufacturing, WRD offers complete pipe mills, serving clients in over 50 countries. Renowned for high precision, efficiency, and energy-saving performance, WRD holds ISO 9001 certification and is recognized as a National Specialized, Sophisticated, and Innovative Enterprise. The company is dedicated to delivering cutting-edge welded pipe production solutions for energy, construction, machinery, and related industries worldwide.

We supply solutions for:

▶ERW tube mills

▶Complete API 5L/5CT tube mills

▶DFT tube mills

▶SSAW pipe mills

▶Welded H-beam mills

▶Hot dipped galvanizing lines/ ZAM tube mill

▶Slitting and Cut-to length line

▶Rollers

Contact WRD

Phone: +86-13752728312 (WhatsApp )

E-mail: info@wrdtubemill.com