API welded pipes are steel pipes specifically designed for the oil and gas industry. As an important component of energy infrastructure, they comply with strict standards such as API 5L and API 5CT to ensure safety and reliability under high-pressure and corrosive environments. They are widely used in oil and gas transportation, drilling casings, and pipeline systems.

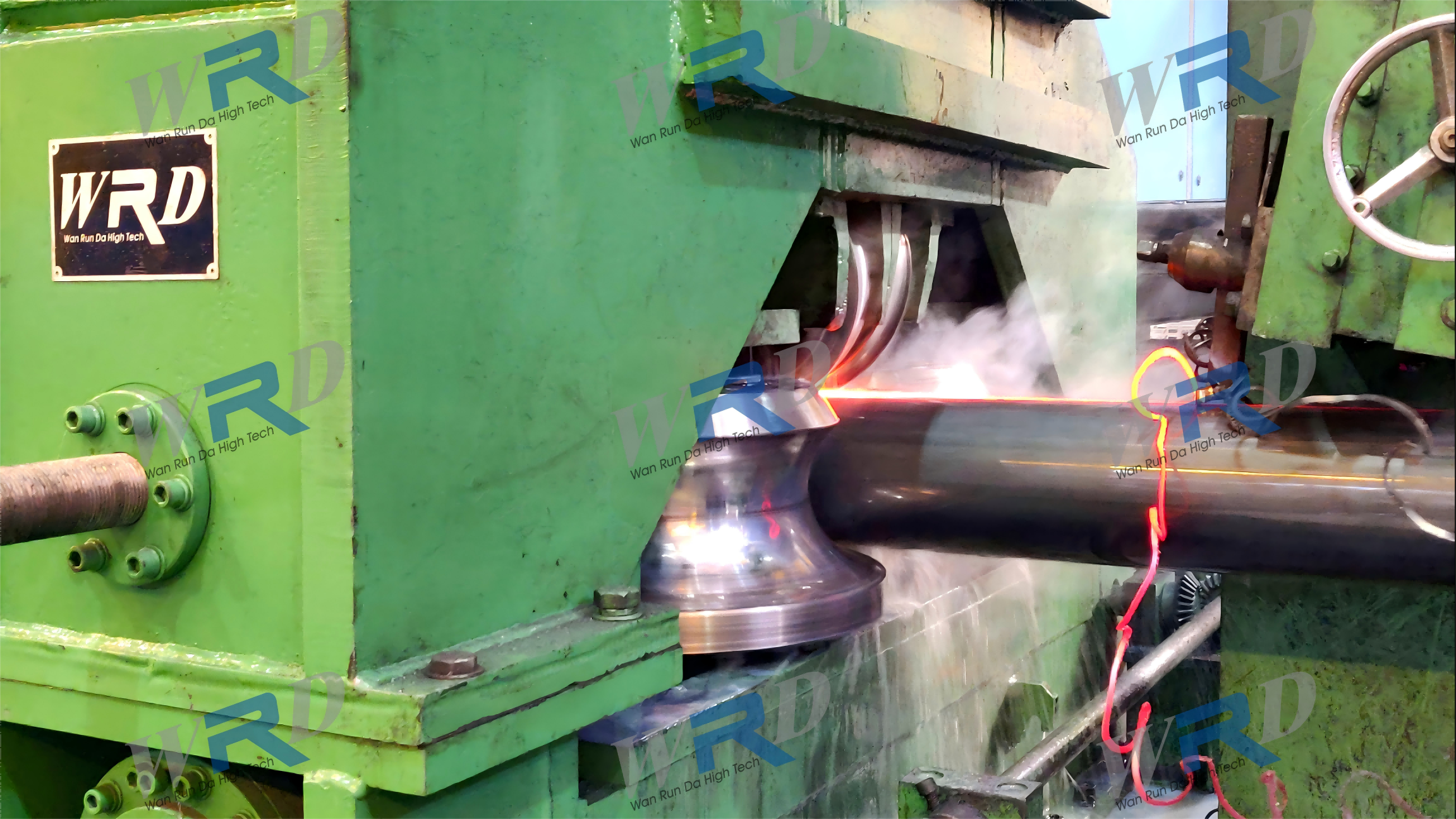

In terms of standards and production processes, the manufacturing of API welded pipes must meet multiple international standards. Among them, API 5L covers the technical requirements for line pipes, including two grades: PSL1 (normal service level) and PSL2 (high-strength, high-toughness service level), with clear specifications for chemical composition, mechanical properties, and non-destructive testing. API 5CT standardizes the technical parameters for oil casings and tubing, with particular emphasis on corrosion resistance and compressive strength. During production, API welded pipes typically employ high-frequency resistance welding (HFW) or submerged arc welding (SAW) processes and must pass quality control procedures such as hydrostatic testing, ultrasonic testing, and X-ray testing to ensure defect-free welds and overall performance compliance.

From the perspective of applications, API welded pipes are mainly used in three areas. In oil and gas transportation, they are used for long-distance transportation of oil and natural gas, requiring excellent high-pressure resistance and corrosion resistance. In downhole operations, API welded pipes serve as casings or tubing and must withstand underground high temperatures, high pressure, and chemical corrosion. Additionally, some API-standard welded pipes are also used in load-bearing structures such as bridges and buildings, fulfilling structural support functions.

As a professional manufacturer of welded pipe equipment, WRD possesses mature experience in the research, development, and manufacturing of API API pipe mill . The company has provided multiple production lines compliant with API 5L and API 5CT standards to global customers, featuring numerous technical highlights. Its high-precision forming technology ensures that pipe diameter and wall thickness tolerances meet stringent API standards. Advanced welding processes, such as high-frequency welding or twin-wire submerged arc welding, achieve weld strength exceeding 95% of the base material. The intelligent inspection system integrates online ultrasonic and X-ray testing to monitor weld quality in real time. Currently, WRD's API pipe mills have been successfully implemented worldwide, helping customers achieve efficient and stable production. In the future, with the growing demand for energy, WRD will continue to optimize its technologies to provide more reliable pipeline solutions for the global energy industry.

About WRD

With long history of expertise in ERW pipe mill R&D and manufacturing, WRD offers complete pipe mills, serving clients in over 50 countries. Renowned for high precision, efficiency, and energy-saving performance, WRD holds ISO 9001 certification and is recognized as a National Specialized, Sophisticated, and Innovative Enterprise. The company is dedicated to delivering cutting-edge welded pipe production solutions for energy, construction, machinery, and related industries worldwide.

We supply solutions for:

▶ERW tube mills

▶Complete API 5L/5CT tube mills

▶DFT tube mills

▶SSAW pipe mills

▶Welded H-beam mills

▶Hot dipped galvanizing lines/ ZAM tube mill

▶Slitting and Cut-to length line

▶Rollers

Contact WRD

Phone: +86-13752728312 (WhatsApp )

E-mail: info@wrdtubemill.com