Heavy duty higher steel grade

▶ Quick-Change System:

Multiple Quick-Change system designs greatly shorten roll changing time, improve production capacity and efficiency.

▶ Optimized Forming:

WFF/WFFX options with adjustable rolls deliver superior product quality.

▶ High automation level:

High automation level, reduce labor costs.

▶ Roll set self made:

All roller sets are self designed and produced.

With more than 25 years experience,We focus on welded tube mill industry and successfully delivered hundreds complete production line solutions worldwide.

Production Range

|

Round steel tube |

Ø219 ~ Ø630mm |

|

Square steel tube |

170x170 ~ 500x500mm |

|

Thickness |

6.0 ~ 25.4mm |

|

Length |

5 ~ 12m |

|

Forming speed |

10 ~ 25m/min |

|

Product standard |

API 5L, ASTM A53, BS1387, ASTM A500, ISO65, etc. |

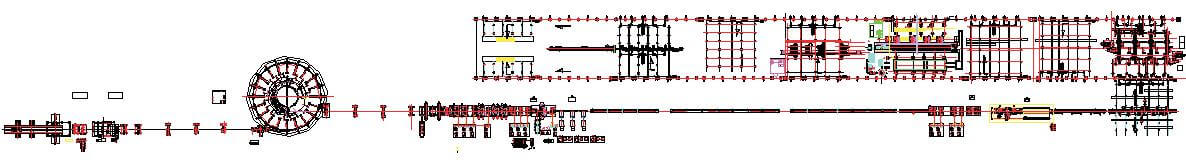

Suppy Scope

- Coil car

- Uncoiler (Hydraulic)

- Pinching roll and Levellers

- Shear & Welder

- Accumulator

- Forming section

- Guiding stand

- High Frequency Welding Machine

- Outer and inner deburr

- Winding machine

- Medium frequency device

- Cooling device

- Sizing section

- Turks-head stand

- Cutting off section

- Conveyor (automatic)

- Straightener

- Double-Sided Stacking Table

- Electrical control system

- Hydraulic and lubrication system

- End facing and beveling machine

- Hydratester

- Auto painting line

- Auto packing line

- Roller

Related Cases

Finished Products

-

MS Steel Pipe

-

MS Steel Pipe