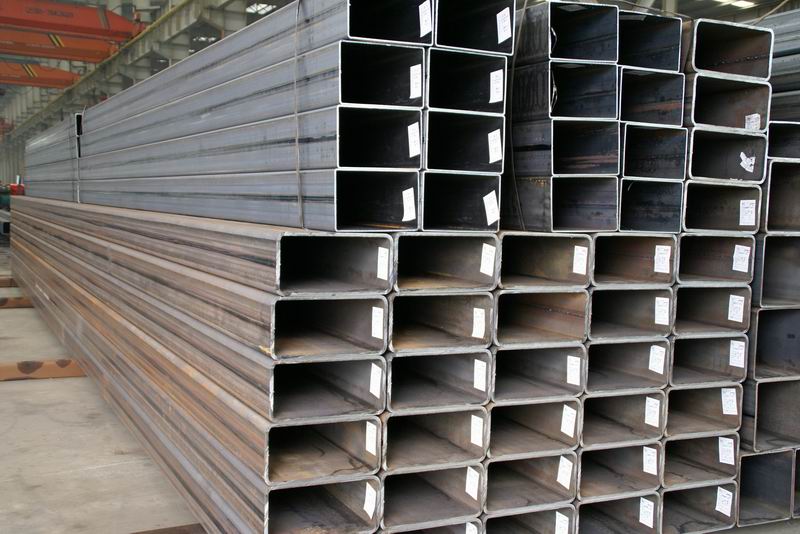

Tianjin Feilong Tube-making Plant Co., Ltd, is one of the national credit enterprise and famous enterprises in Tianjin, was founded in 1995, the existing 1000 employees, fixed assets of 140 million yuan. With an annual output of 426 million tons of welded steel pipe.

WRD began to cooperate with Feilong at the beginning of its establishment. So far, we have cooperated with Feilong for nearly 20 years. And 2/3 of Feilong's equipment is provided by WRD.

|

Item |

Model |

Sets |

Time |

Location |

|

1 |

ERW 76×4.0mm Tube Mill |

1 set |

2003.11 |

China |

|

2 |

ERW114×5.0mm Pipe Mill |

1 set |

2004.6 |

China |

|

3 |

ERW50×3.5mm Tube Mill |

1 set |

2009.01 |

China |

|

4 |

ERW 76×4.0mm Tube Mill |

1 set |

2009.6 |

China |

|

5 |

ERW 50×3.25mm Tube Mill |

1 set |

2009.6 |

China |

|

6 |

ERW89×4.0mm Tube Mill |

1 set |

2010.3 |

China |

|

7 |

Modification of ERW76 Tube Mill into ERW114 Pipe Mill |

1 set |

2010.4 |

China |

|

8 |

Modification of ERW89 Tube Mill into ERW114 Pipe Mill |

1 set |

2010.6 |

China |

|

9 |

ERW 60×3.5mm Tube Mill |

1 set |

2010.8 |

China |

|

10 |

Modification of ERW165 Pipe Mill into ERW180 Pipe Mill |

1 set |

2011.6 |

China |

|

11 |

ERW60×3.5mm Tube Mill |

1 set |

2011.8 |

China |

|

12 |

ERW50×2.5mm Tube Mill |

1 set |

2011.6 |

China |

|

13 |

ERW219×12.0mm Pipe Mill |

1 set |

2011.8 |

China |

|

14 |

Modification of ERW219 Tube Mill into Push-to-Square Pipe Mill |

1 set |

2022.5 |

China |

At the early 2022, we received a request from Feilong to upgrade the tube mill. The WHFW219 tube mill mainly produces square tubes and adopts “round-to-square” technology. This process can no longer meet the increasingly stringent requirements of the market for the square pipes. Feilong is eager to upgrade this tube mill.

Our engineers proposed the “push-into-square” technology according to the customer's requirements. The theory is to use the motors at sizing to push the tube in the turks-heads, and only the sizing section will be modified. It is a mature technology which widely used a nd it is the best method to make the square pipe into perfect shape(perfect R angles).

Feilong quickly confirmed our proposal and placed the order. After three months of manufacturing, installation and commissioning, the pipe mill has been put into use successfully, which makes Feilong steel pipes more reliable and high-qualified.

WRD will support lifelong service to clients for equipment renovation to maximize production capacity. Our R&D working group will be closely involved and give our professional advice and suggestions. Help factories turn ideas of transformation into reality. Our team also gets a lot of inspiration from it to continuously improve our production line.