In the industrial and construction sectors, steel pipe coating technology is transforming perceptions of traditional piping materials with its unique dual value. This surface coating process not only provides pipes with sturdy "protective armor" but also dresses them in diverse "visual attire," making it an indispensable component of modern engineering. Painting line can be a important section of tube mill.

The core advantage of pipe coating lies first in its exceptional protective capabilities. Coatings such as epoxy resin and polyester powder form a dense barrier, effectively isolating the pipe from air and moisture, preventing rust at its source. Test data shows that high-quality coated pipes can extend their corrosion resistance by 3-5 times in outdoor environments.

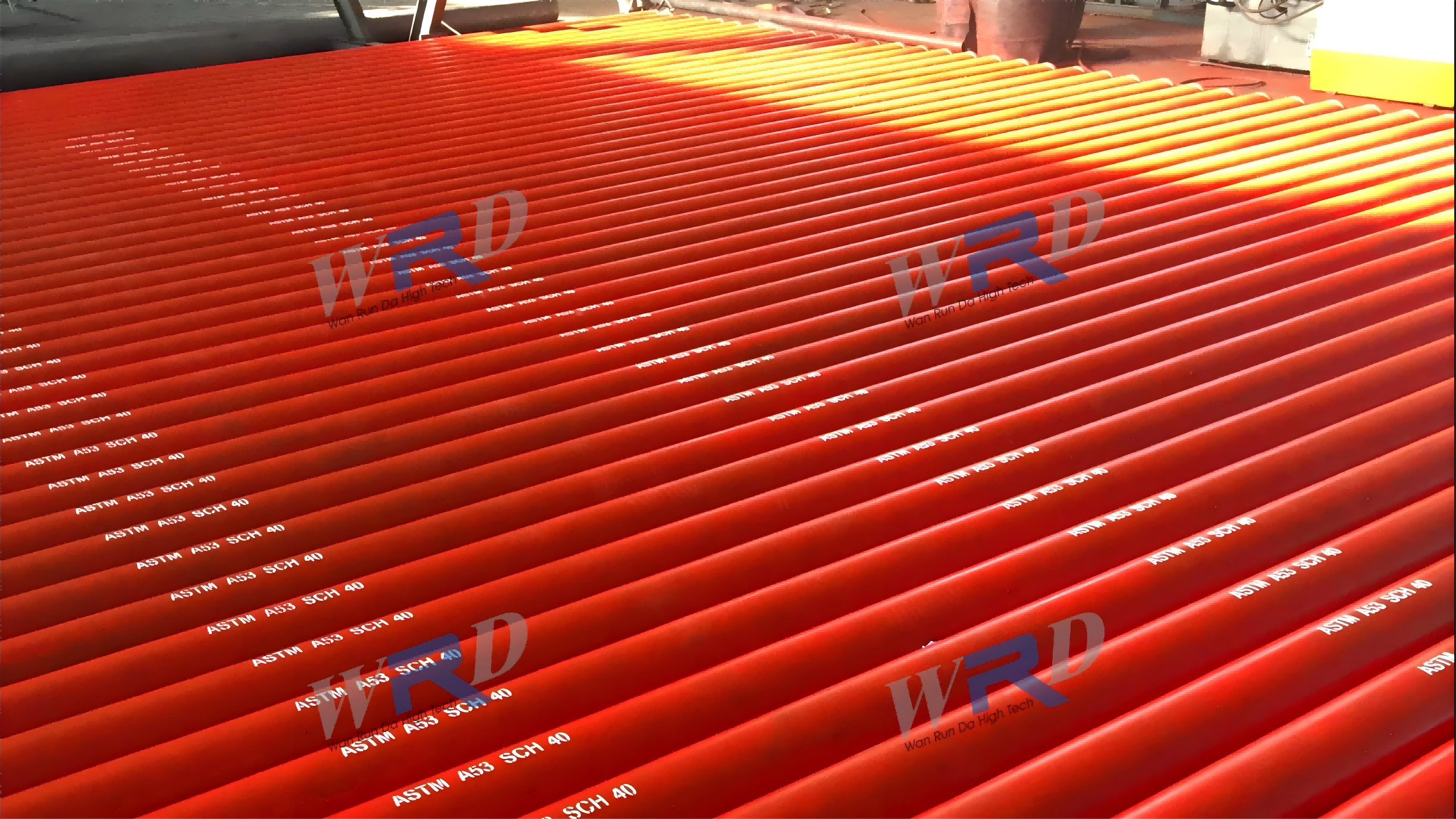

Additionally, the coating reduces scratches and damage during transportation and installation, making it particularly suitable for construction pipes that require frequent handling. Notably, different colored coatings serve important identification functions—red for fire pipes, yellow for gas pipes—this intuitive color coding significantly reduces installation errors and enhances project safety.

In balancing aesthetics and practicality, pipe coating demonstrates remarkable flexibility. A rich palette of colors brings life to cold steel pipes:

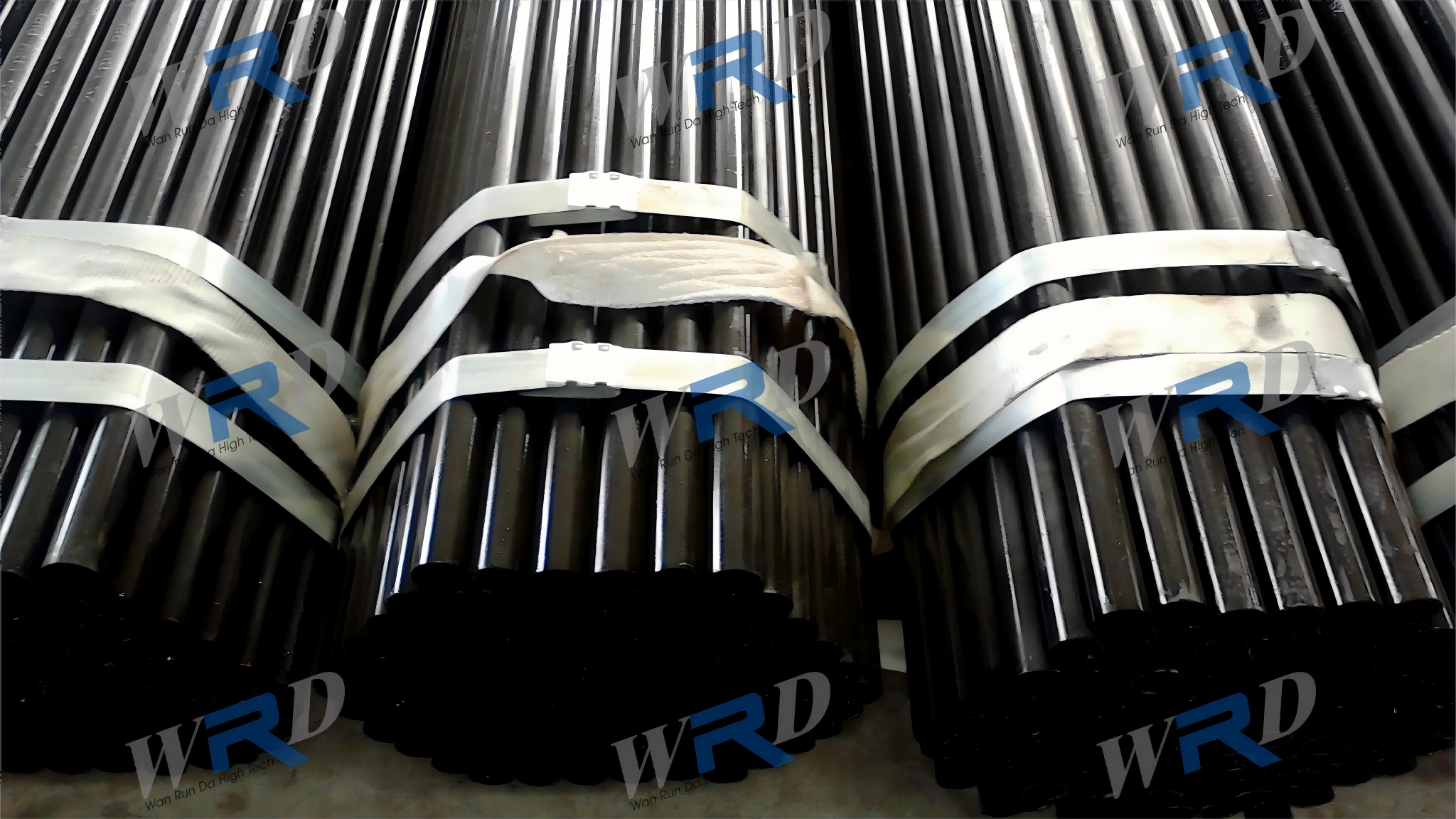

- Black and dark gray are commonly used for industrial equipment frames, projecting a professional and sturdy appearance.

- Green suits agricultural greenhouses and garden structures, blending with natural surroundings.

- Blue serves as the signature color for water supply and drainage pipes.

- Red and orange function as safety warnings in fire protection systems.

- White and light tones bring minimalist beauty to building facades and interior decor.

This color language not only meets aesthetic needs but also achieves perfect harmony between function and beauty.

Technological advancements continue to upgrade pipe coating. Modern electrostatic coating can precisely control thickness (50-150μm) and cure at temperatures below 200°C, ensuring both energy efficiency and coating uniformity. Indoors, the color retention period can exceed 10 years. With the integration of nanotechnology, smart coatings featuring self-cleaning and high-temperature resistance are emerging. The future of pipe coating will expand beyond basic protection and decoration into broader functional applications, creating new possibilities for industrial development.

About WRD

With long history of expertise in ERW pipe mill R&D and manufacturing, WRD offers complete pipe mills, serving clients in over 50 countries. Renowned for high precision, efficiency, and energy-saving performance, WRD holds ISO 9001 certification and is recognized as a National Specialized, Sophisticated, and Innovative Enterprise. The company is dedicated to delivering cutting-edge welded pipe production solutions for energy, construction, machinery, and related industries worldwide.

We supply solutions for:

▶ERW tube mills

▶Complete API 5L/5CT tube mills

▶DFT tube mills

▶SSAW pipe mills

▶Welded H-beam mills

▶Hot dipped galvanizing lines/ ZAM tube mill

▶Slitting and Cut-to length line

▶Rollers

Contact WRD

Phone: +86-13752728312 (WhatsApp )

E-mail: info@wrdtubemill.com